Particle Handling by Electric Field[1]

Keywords: Electrostatic force, Particle, Particle conveyance, Micro-parts handling

1. Introduction

Traveling electric fields have been applied in mass transportation of powder by an electric curtain[2], where fine particles are levitated against the gravity.

In order to provide such devices which can convey particles more precisely and with more flexibility of manipulation like sorting, several devices have been developed.

The characteristic of the drive methods is that particles are not levitated but conveyed along or very close to the surface of cover film which insulates the electrodes.

2. Principle of conveyance

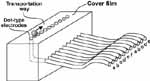

Balanced, multi-phase high voltages are supplied to a series of encased, parallel electrodes which are covered and protected against electric sparkovers by a thin insulating film.

Upon the activation, a traveling electric field is created around the electrodes.

Particles on the film-surface become charged, and when the dynamic forces of the electric field overcome adhesion and gravitational forces, particles move with the traveling field in a direction perpendicular to the electrodes as shown in the structure of the electric panel in Figure 1 and 2.

By this transportation process, particles proceed stepwise from electrode to electrode, producing an overall conveyance velocity in direct proportion to the frequency and the electrode gap.

A multi-channel, PC-controlled, high voltage supply is linked to the panel, where every sixth electrode belongs to the same phase state: a, b, c, d, e, or f.

Particle motion depends on the property of particles, effective gap from activated electrodes and patterns of applied voltages.

Various particle materials with a 5µm to 400µm diameter range have been examined in experiments; Fe, Al, glass, and plastic spheres showed the best performances.

|

| Figure 1: Electric panel device |

|

|

| Figure 2: Intersection of electric panel device |

|

3. Various devices for handling

Three structurally novel devices were developed: the electric panel, the electric tube and the electric dots.

Each incorporates the same principle for particle handling, but serves a different purpose.

ELECTRIC PANEL DEVICE

|

As shown in Fig.1, the device is composed of parallel electrodes encased in epoxy resin, an insulating thin cover-film, a supporting panel.

Due to the simple electrode design, the panel can be fabricated with various features.

An approach to achieving two-dimensional particle handling is shown in Figure 3.

A mesh electric panel, which interweaves the insulated electrode wires for X drive with those for Y drive, can convey groups of particles in X and (or) Y direction.

|

| |

Figure 3: Electric panel for XY manipulation

|

|

ELECTRIC TUBE DEVICE

|

The cross section of an electric tube device with 6 phases is shown in Figure 4.

This structure is very easy to fabricate.

To make a tube of a number of phases, the same number of insulated wires are spooled as shown in Figure 4.

The particles can be transported along the inside surface of the tube.

By this device, small aluminum balls with 0.2mm diameter could be easily conveyed upward against the gravity.

This device is also suitable for long distance transportation of particles.

|

| |

Figure 4: Electric tube device

|

|

ELECTRIC DOTS DEVICE

|

Fig.5 illustrates the concept of the electric dots device.

The manipulation electrodes appear as a matrix of dots in the handling surface.

The device incorporates a bundle of insulated conductive wires, embedded in a supporting body.

The surface has been ground in a plane normal to the wires to form the handling surface which is subsequently covered by a thin film.

The particles are manipulated on the film-surface along the dot electrodes.

Particles are handled precisely from dot to dot.

|

| |

Figure 5: Electric dots device

|

|

See also

References

[1]F.Moesner and T.Higuchi, "Devices for particle handling by an AC electric field", Proc. of IEEE Workshop on Micro Electro Mechanical Systems, pp.66-71 (1995)

[2]S.Masuda and T.Kamimura, "Approximate methods for calculating a non-uniform traveling electric field", Journal of Electrostatics, Vol.1, pp.351-370 (1975)